E-PTFE Gasketing Tape

E-PTFE Gasketing Tape

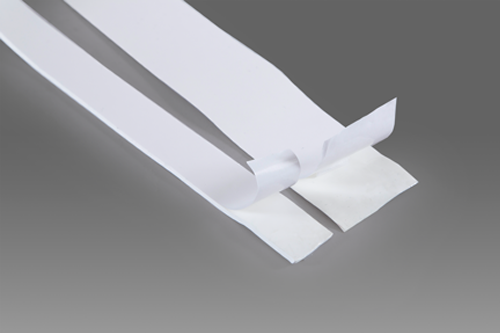

ePTFE Isotropic Gasket Tape (or called as I-Tape) is a multi-directionally expanded PTFE material in tape form, and can be formed in place quickly, installed easily and reduces expensive material scrap effectively. ePTFE I-Tape is produced with a full adhesive backed.Typical applications include glass lined steel reactors, large diameter equipment, mating flanges with a tongue-and-groove sealing area, and surfaces that may be highly deflected.

Material Properties

Made of 100% pure PTFE, expanded via a unique process into a consistent, highly fibrillated structure. Upon compression, the fibrils lock together to form a strong, uniform material, impervious to gases and liquids.

It seals under extreme temperatures, pressures and against corrosive media, where conventional materials would break down. Even during application, the material is incredibly resistant to creep, relaxation and cold flow - issues which are often associated with other gasket materials, especially virgin or filled PTFE.

Operating throughout the pH range, resistant to thermal cycling, non-contaminating and therefore can be used in virtually any industry, sealing the simplest to the most difficult of gasket applications.

You can Depend on These High Performance Features

- Wide pressure and temperature range

- Unsurpassed chemical compatibility

- Excellent creep and cold flow resistance

- Will not harden or deteriorate with age

- Low coefficient of friction allows easy removal

- Easily conforms to damaged or pitted flanges

- Low compressive load to seal

- Wide adhesive strip for easy installation

- "Sheet Gasket on a Roll”

- Professional engineering support

TEMPERATURE RANGE:

- -450° F (-268° C) TO

- +600° F (315° C)

PRESSURE RANGE:

- Full Vacuum to 3000 psi

- (20.7 Mpa/ 207 Bar)

CHEMICAL COMPATIBILITY:

- 100% Expanded virgin PTFE

- pH Range: 0 to 14

- Chemically inert except for elemental fluorine and molten alkali metals

FDA COMPLIANT:

- Meets FDA 21 CFR177.1550

LOW CREEP AND COLD FLOW

NON-TOXIC, SILICONE-FREE

NON-CONTAMINATING

NON-PARTICULATING

NON-AGING IN SERVICE

- Aerospace

- Oil and Gas

- Automotive

- Pharmaceutical and Medical

- Chemical Processing

- Power Generation

- Electronics

- Pulp and Paper

- Food and Beverage

- Wastewater Treatment

- Marine

- Semiconductor