O-ring Selection

STEPS FOR SELECTING SUITABLE O-RING THAT APPLICATIONS DEMANDS:

STEP 1: CHOOSING ENCAPSULATION

|

FEP Teflon® Tubing |

PFA Teflon® Tubing |

|

A wide chemical resistance |

All the benefits of FEP tubing |

|

Temperature range of -60 to 205 degree Celsius (-76 to 400 degree Fahrenheit) |

A higher temperature range -60 to 260 degree Celsius (Short duration 300°C) |

|

Low compression set |

A higher/more mechanical strength |

|

Low coefficient of friction |

An increased stress and crack resistance |

|

High corrosion resistance |

Longer wear ability |

|

FDA,USP CLASS VI,SANITARY 3A COMPLIANT |

FDA,USP CLASS VI,SANITARY 3A COMPLIANT |

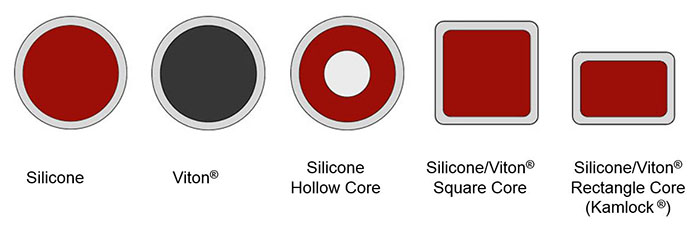

STEP 2 : INNER CORE SLECTION

Inner Core / Profile Options

-

Silicone Inner Core

Commercially best material option combined with lower Shore Hardness and greater elasticity than Viton®, providing an excellent material choice for the majority of applications.

Shore Hardness average of the seal is;

85-90 Shore A for solid core Silicone

Chemours FEP CJ95 ASTM D-2116-07 type IV: 5000 psi

Viton® Inner Core

Greater chemical resistance than Silicone. If encapsulation is damaged, Viton® provides greater resilience to chemical attack.

Shore Hardness average of the seal is;

90-95 Shore A for solid core Viton®

Chemours FEP CJ95 ASTM D-2116-07 type IV: 5000 psi

-

Silicone Hollow Inner Core

Greater compressibility than solid Silicone core, with a hardness similar to a standard elastomeric 'O'-Ring. The hollow core flexibility means less clamping force is required to enable its sealing abilities. Ideal for fragile applications using sensitive materials, such as glass or light plastics. Useful for where the sealing area may require room for movement during operation.

75-80 Shore A for hollow core Silicone®

Chemours FEP CJ95 ASTM D-2116-07 type IV: 5000 psi

The degree of squeeze best recommended is;

15/22% for static applications

10/15% for dynamic applications

8/10% for pneumatic applications